Calibration Service with Certificate for U6/UE9/T7/T8

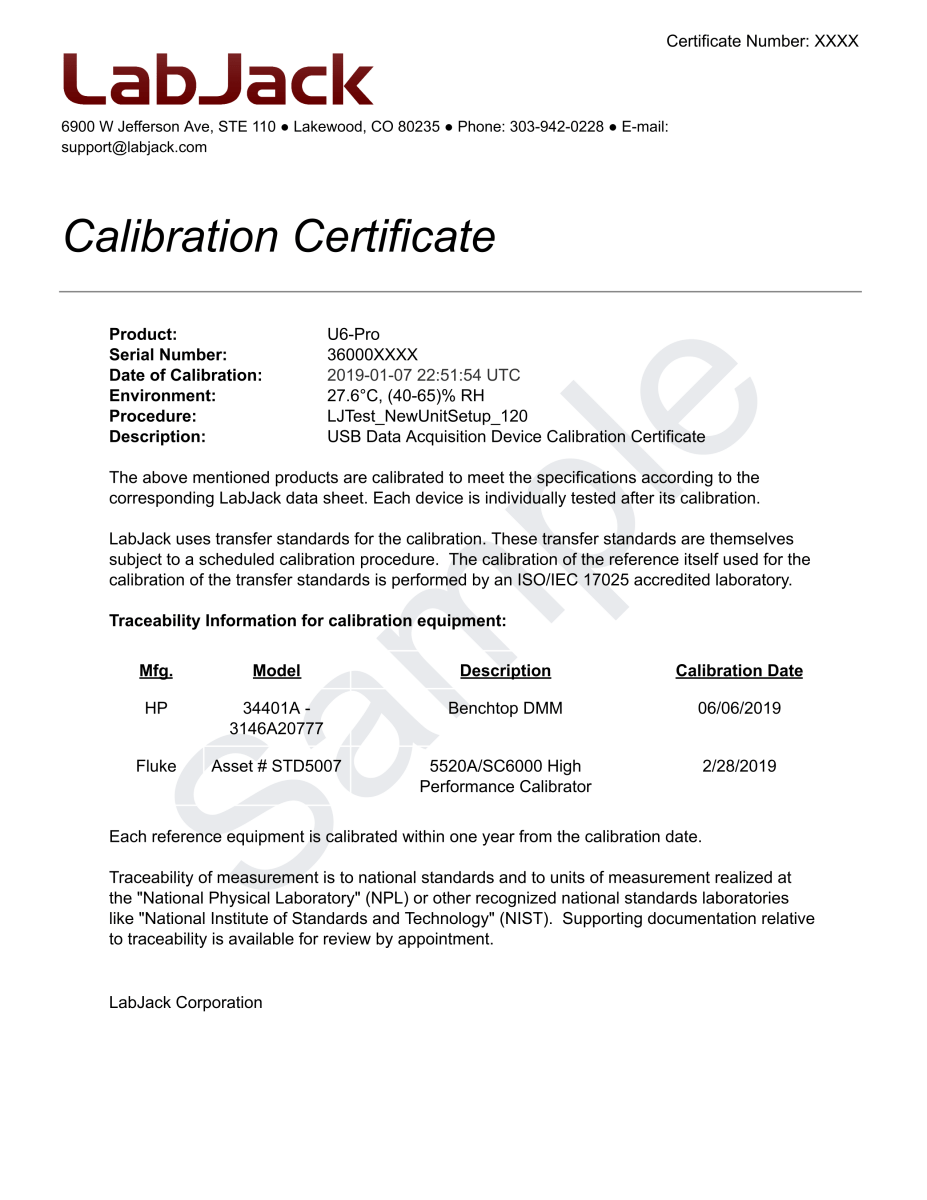

NIST traceable calibration of the U6/U6-Pro (and all OEM variants), T7/T7-Pro (and all OEM variants), UE9/UE9-Pro, or T8. Industry standard calibration interval is once per year. This service includes a calibration certificate.

All devices are calibrated at the factory, but there are a few reasons for purchasing this calibration certificate service:

- A certificate is needed. Due to the nature of our production process, it is not cost effective to generate a certificate for the original factory calibration, so one is not included with a normal purchase.

- Recalibration is needed. Many organizations or processes that require a calibration certificate also require that devices be recalibrated or verified at some interval. 1 year is the industry standard interval.

- A "fresh" calibration is desired. Since we try to keep substantial stock on hand to provide immediate shipment of all orders, it is possible that the factory calibration could happen some months before a device ships.

OEM Variants

OEM boards can be calibrated as long as they have not been customized in a way which prevents them from fitting in our test and calibration jigs. Most standard pin headers will fit. Large guards, standoffs, or right angles can be a problem.

FAQ

Is my calibration good?

Please see How Do I Test and Verify a LabJack is Calibrated?

How often is calibration required?

The industry standard for calibrations is yearly. The actual requirement will be dictated by your policies or specific regulations/requirements you are following, but short of that, yearly can be used as an industry standard interval.

Is the LabJack calibration important?

Usually not. Calibration of an entire system is usually important, but often the specific calibration of the LabJack analog I/O is not needed. There are usually other errors that are part of the measurement so the best practice is to do a single calibration of the entire signal chain in-situ, rather than calibrating each part separately. For example, here are some (but not all) error sources that combine when doing a quarter bridge measurement with a strain gauge:

- Accuracy of the excitation voltage (output is proportional to excitation).

- Accuracy specification of the strain gauge.

- Accuracy of the bridge completion resistors.

- Accuracy of the math relating strain to voltage.

- Errors due to resistance of connections and wires.

- Errors due to mounting of the strain gauge.

- Accuracy of the LabJack A/D conversion.

Note that only 1 of these 7 prominent error sources is from the LabJack. You could calibrate this system by individually calibrating each of the 7, and then doing a statistical analysis to combine all those errors, but whenever possible it is much better to calibrate the system end-to-end, so in this case relate applied force to voltage read in software. Say this strain gauge measurement is to measure force applied to a beam. A great way to handle this is to apply 2 known forces (0 pounds is one easy force to use), note the 2 associated digitized voltages, and then come up with a slope & offset that relate volts to force and apply this in software.

What about the U3 and T4?

The U3 and T4 are calibrated at our facilities to within the specs found in their datasheets, but we do not offer a NIST traceable calibration service for these devices at this time. A couple reasons in addition to some of the information above:

- The cost of the calibration service compared to the cost of the device is such that it would not make sense for most customers.

- The current high-efficiency process used to manufacture and calibrate these lower cost devices does not lend itself to cost efficient generation of NIST traceable certificates.

What is the typical lead time?

We estimate that it will take 1-3 days for us to perform calibration services, starting from the date that your device(s) arrive at our office.

What should I do if I need to place an order for a new device with calibration services?

Add the calibration certificate service to your order with the device(s) (one calibration certificate service per device to be calibrated) and we will perform the service on your device(s) before shipping the order to you. Please note which device(s) the calibration certificate is for on multiple device orders.

What should I do if I already have a device and I would like to calibrate it?

We ask that you place an order for the calibration service (one calibration service per device to be calibrated.) From there, our team will send you a follow-up email with the following information:

- The address to ship the device to.

- Instructions on how to ship the device(s) back to us and referencing the order number on the package.

If I am shipping in a device for calibration services, who is responsible for shipping costs?

We ask that you pay to ship the device to our office, then we will handle shipping back to you.

for U.S. Orders $150+

5-Year Warranty

60 Days Money back

Stock status: In Stock